When you think about the manufacturing industry, you might picture big machines, workers in hard hats, and assembly lines. However, behind all this, there is a quiet revolution brewing. One bright star in this revolution is CNC tube bending. It’s a not-so-glamorous name, but believe me, it is revolutionizing the making of things, and more importantly, it is making manufacturing far more efficient, precise, and versatile. So, what is CNC tube bending, and why is it such a big deal? Let’s dive in.

What is CNC Tube Bending?

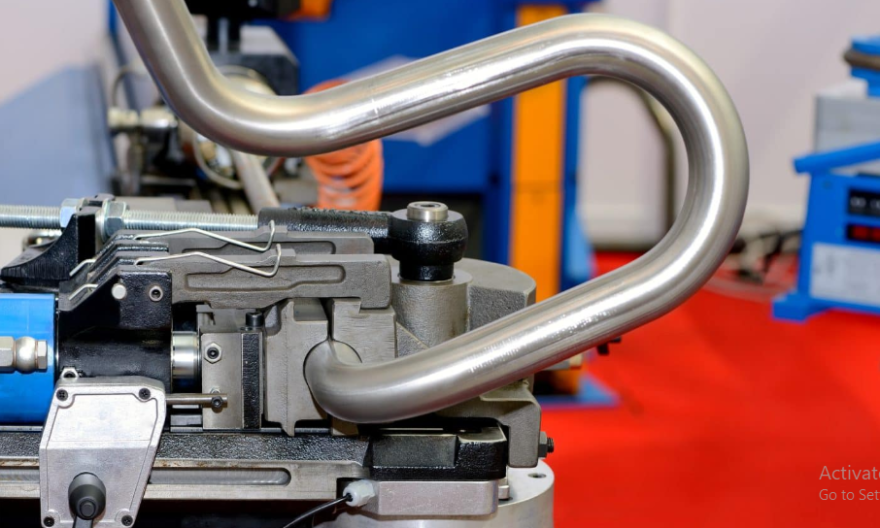

First, let’s break it down. CNC stands for “Computer Numerical Control.” In brief, it means using computers to control machines. In this case, the machine bends metal tubes into specific shapes with incredible precision. It is a lot like high-tech origami but working with metal tubes instead of paper.

Whether it is the handle bars of your bicycle, the exhaust pipes on your car, or the tubes in your hospital bed, these curved metal pieces don’t occur by pure luck. They are carefully designed and shaped to perfection, often using the method known as CNC tube bending.

The Old School Way Vs. CNC Tube Bending

Previously, tube bending was done with a manual approach or semi-automatic machine. True, it accomplished the task at hand, but in this case, slow, laborious, and often included human errors that could throw an entire part into the dust bin if one side of a bend was off only a little. Besides, very complicated shapes made life tough and it needed a great amount of trying out.

All these change with CNC tube bending. The process is automated by computers controlling every move made with the machinery. In it, the operator does nothing more than input the design, and the rest of the work is handled by the machine. The outcome? Perfect bends every time, even for complicated designs.

Why is CNC Tube Bending a Game-Changer?

Now that you know what CNC tube bending is, let’s talk about why it’s shaking things up in the manufacturing world.

- Unmatched Precision

Accuracy is one of the major benefits of CNC tube bending. Parts made for cars, airplanes, and medical devices cannot afford to be off by a hair’s breadth, or disaster may strike. The CNC machines bend tubes to precise tolerances down to a fraction of a millimeter. The precision guarantees perfect fitting every time.

- Rapid Production

Time is money, particularly in manufacturing. Conventional tube bending techniques were lengthy because every piece needed to be bent manually or adjusted repeatedly. With the CNC machine, the same tube can bend several tubes in quick time and efficiently, thus reducing production time by a substantial margin.

- Design Flexibility

Ever seen a car exhaust with twists and turns that look impossible to make? That’s the magic of CNC tube bending. The technology allows for incredibly complex designs that would be almost impossible to achieve manually. This opens up new possibilities for engineers and designers, allowing them to create innovative products without being limited by traditional manufacturing methods.

- Cost Savings

While CNC machines require an initial investment, they save money in the long term. Less waste, faster production, and fewer errors mean reduced costs on the long run. Additionally, with the machine, it can cut through different materials such as aluminum, steel, and copper, making them versatile for different industries.

- Consistency

In manufacturing, consistency is king. Whether you’re making one part or a thousand, each one needs to be identical. CNC tube bending ensures that every bend is exactly the same, no matter how many pieces you produce.

Where is CNC Tube Bending Making an Impact?

You might not realize it, but CNC tube bending plays a role in many industries:

- Automotive: From exhaust systems to roll cages, CNC tube bending ensures that every part fits perfectly, improving vehicle performance and safety.

- Aerospace: Precision is critical in airplanes, where even small errors can have big consequences. CNC technology helps create lightweight, reliable components.

- Medical: Think hospital beds, wheelchairs, and surgical equipment—all rely on perfectly bent tubes for their frames and structures.

- Construction: Sleek curved designs with curved metal elements can be achieved using the process of CNC tube bending.

- Furniture: Such technology contributes significantly to making the furniture smooth, minimalist, and curvy in style.

The Future of Manufacturing

CNC tube bending is a part of a much larger trend of automation and smart manufacturing. Further innovations are ahead as technology becomes more sophisticated, and it can be visualized that in future, robots working alongside CNC will produce parts even faster and at a level of complexity than can be thought of today.

This technology also goes in line with the increasing interest in sustainability. As a method of cutting waste and manufacturing in a more efficient way, CNC tube bending can lead to more sustainable production techniques. It’s a win-win for both businesses and the planet.

Conclusion

Of course, CNC tube bending may not seem as glamorous as electric cars or AI, but it is the ultimate example of small innovations leading to big changes: it’s speeding up manufacturing and reducing costs, all while offering designs that have not been previously possible.

Next time you hop on your bike, sit in a chair, or drive your car, take a moment to appreciate the magic of CNC tube bending service. It’s proof that even the smallest parts of our everyday lives are shaped by cutting-edge technology. Who knew bending metal tubes could be so exciting?